December 16, 2025

Closing the Visibility Gap in Interior Construction

In construction, visibility is one of the most important factors in maintaining efficiency, safety, and accountability. Exterior jobsites often benefit from wide sightlines and plenty of space for cameras or observation points. Cranes, steel frameworks, and crews are visible from a distance, giving owners and stakeholders confidence that progress is being made.

Once work moves indoors, the situation changes. Walls, ceilings, and evolving layouts obscure activity. Multiple trades overlap in confined areas, making it difficult to track progress or spot risks. Managers often find that the tools which worked well outdoors are less effective once the project transitions inside.

This visibility gap has real consequences. Without clear documentation, disputes over completed work are more common, safety issues may go unnoticed, and managers are forced to spend more time on repetitive site visits just to verify progress. For projects with tight budgets and aggressive timelines, these blind spots can quickly translate into higher costs and delays.

Why Traditional Monitoring Falls Short

Many project teams have relied on fixed-position cameras or 360-degree views to capture interior activity. While these tools can be helpful, they often prove insufficient. A static camera cannot adapt to shifting floorplans, meaning that once walls or partitions go up, large portions of the jobsite may fall out of view. Wide-angle cameras sometimes lack the resolution needed to verify workmanship or detect smaller but costly mistakes.

Because these limitations are significant, many teams still depend on walkthroughs and manual photos. Although useful, walkthroughs are subjective, time-consuming, and inconsistent. They provide snapshots rather than continuous, shareable records. What interiors require is a monitoring solution that combines flexibility, adaptability, and intelligence.

How Mobile Robotic Monitoring Address the Challenge

Recent advancements in mobile robotic cameras are beginning to change how interior construction is documented. These systems bring together mobility, precision, and AI-based intelligence in ways that directly address long-standing visibility challenges.

The first advantage is mobility. Robotic systems mounted on portable stands can be moved quickly as construction progresses, ensuring coverage keeps pace with evolving layouts. Unlike static cameras, they do not become obsolete once walls shift or rooms are subdivided.

The second advantage is robotic pan, tilt, and zoom control. With the ability to scan entire rooms in real time, project managers can capture broad views and then focus on critical details such as the quality of finish work, the alignment of mechanical systems, or the placement of fireproofing materials.

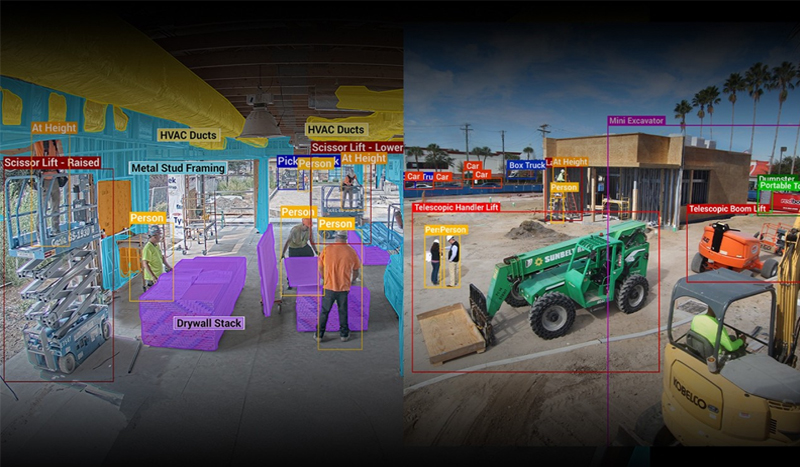

The third advantage is the integration of AI-powered visual intelligence. Panoramic imaging can be annotated automatically to identify work in place, track materials, and confirm compliance with safety standards. These annotations provide objective evidence that supports dispute resolution and accelerates verification.

Finally, many robotic systems incorporate environmental monitoring. Air quality sensors detect particulate matter, volatile organic compounds, and carbon dioxide levels, helping ensure safer working conditions. This additional layer of monitoring reduces exposure risks for crews and contributes to healthier environments for future occupants.

When combined, these capabilities transform monitoring from passive observation into active intelligence. Instead of just collecting images, teams gain actionable data that informs decision-making and improves outcomes.

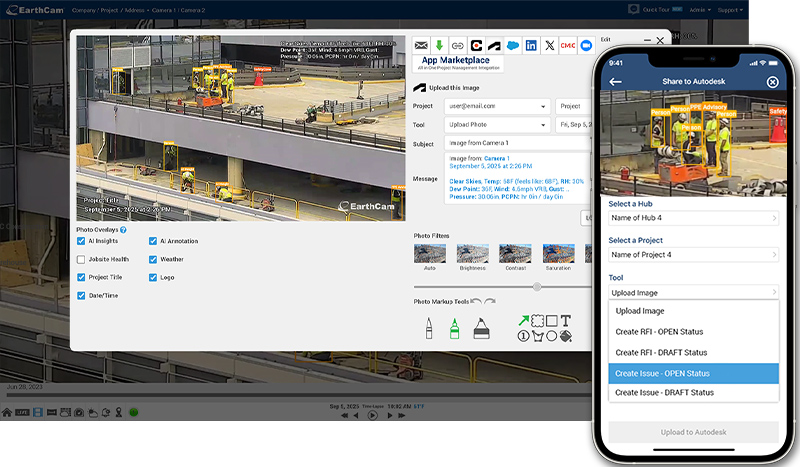

An Example: The Mobile StreamCam Robotic

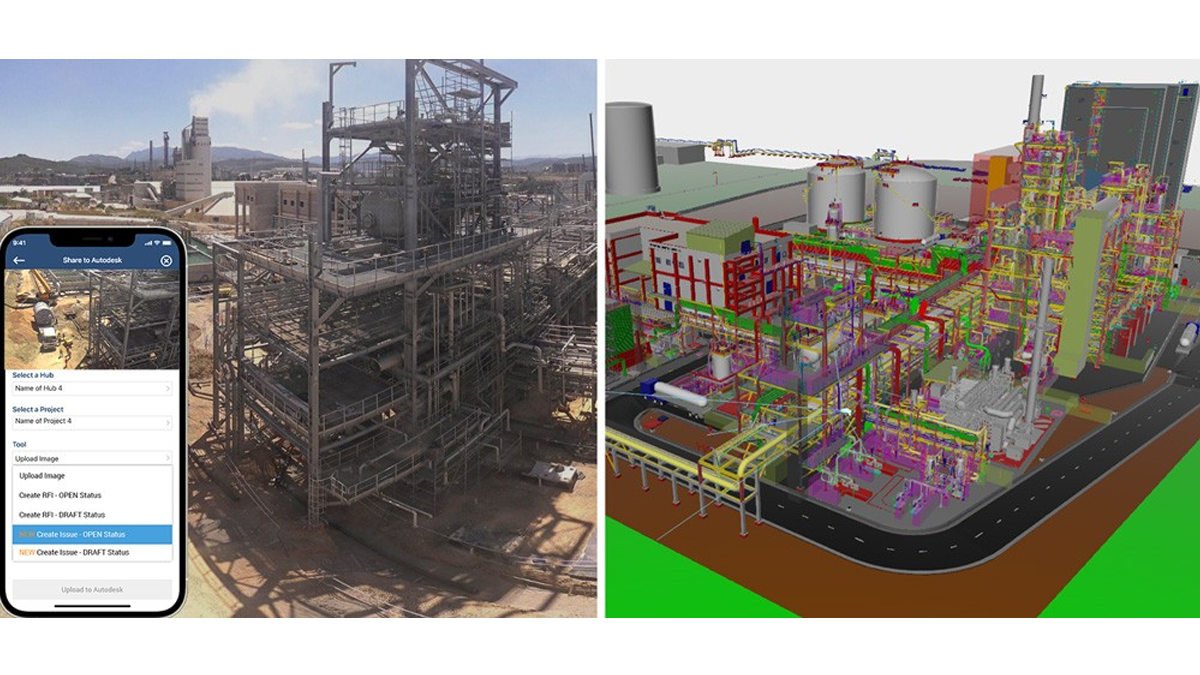

EarthCam’s Mobile StreamCam Robotic illustrates how these features are being designed specifically for interior construction. It provides flexibility by allowing users to reposition the unit as layouts evolve. The robotic controls enable managers to scan entire rooms or zoom in remotely through EarthCam’s Control Center platform or mobile app.

The system’s AI-driven Panoramic Visual Intelligence creates annotated visuals that capture both progress and materials in place. These records are objective and time-stamped, giving stakeholders a reliable source for resolving disputes. The inclusion of air quality monitoring adds a safety dimension that is especially valuable in enclosed environments where particulates or VOCs can build up quickly.

This combination of flexibility, detail, and intelligence ensures that teams are not just collecting footage but building a continuous narrative of project activity.

Why Visibility Matters to Stakeholders

Transparency is a common demand among owners, lenders, contractors, and designers. Owners and lenders often require proof of progress before releasing payments or authorizing new phases. Contractors want to minimize travel and repeated site visits. Designers and engineers need assurance that specifications are followed accurately.

Robotic monitoring provides each of these groups with a verifiable record of interior activity. Everyone can reference the same objective data, which strengthens trust and accelerates decision-making. Because the information is searchable, annotated, and stored securely, accountability is improved across the project.

For complex and high-profile builds such as hospitals, airports, and cultural institutions, this level of clarity is particularly valuable.

Beyond the Construction Phase

The benefits of robotic monitoring do not end once a project is completed. The full visual and environmental record becomes part of the project closeout documentation, providing long-term value for owners and facility managers.

Detailed records can assist with warranty claims, renovations, and maintenance planning. Time-lapse sequences and annotated visuals can also be used by marketing and communications teams to showcase the project to stakeholders or the public. Years after completion, facility managers may still refer to the visual archive to understand how systems were installed or where utilities are located.

The result is a resource that continues to provide value long after the last crew has left the site.

The Future of Interior Monitoring

As demands for speed, safety, and accountability grow, the need for smarter monitoring solutions will continue to increase. Interior projects have always presented unique challenges, but advancements in robotics, AI, and environmental sensing are closing the gap.

Solutions such as EarthCam’s Mobile StreamCam Robotic demonstrate how technology can transform interiors from some of the least visible spaces on a jobsite into environments where stakeholders have confidence and clarity. Instead of blind spots, there is complete situational awareness. Instead of fragmented records, there is a continuous, verifiable account of progress.

This change represents more than an upgrade in technology. It reflects a shift in how construction professionals approach documentation and management. By addressing visibility gaps, project teams are better equipped to deliver safer, higher-quality, and more efficient outcomes.